Capability Study Template

Capability Study Template - Web use normal capability analysis to evaluate the potential (within) and overall capability of your process based on a normal distribution. Web struggling with process capability analysis? It involves collecting data on process characteristics and calculating. Web how to perform a process capability study. The base of the calculation is a spreadsheet without macros. Comparing the output to the spec. Web download the blank lean business model canvas template for google slides. Web process capability analysis: The following is an excerpt from the quality engineering handbook by thomas pyzdek, © qa publishing, llc. It involves calculating capability indices like cp, cpk,. When to use this template: Web how to perform a process capability study. Web capability analysis is a critical tool for ensuring process performance meets specifications and requirements. To calculate adjusted values, you need the microsoft certified „sixsigmablackbelt analysis“ excel „add in“. Web determine if your process meets specifications and is statistically controlled. Web capability analysis is a critical tool for ensuring process performance meets specifications and requirements. Web business capability analysis technique template. Web the steps for conducting a process capability study are: Web capability analysis is a statistical methodology used to determine process capability. Web struggling with process capability analysis? Web capability analysis is a statistical methodology used to determine process capability. A few ways a process capability study. When to use this template: Web struggling with process capability analysis? Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. Web business capability analysis technique template. Web process capability analysis: Web capability analysis is a critical tool for ensuring process performance meets specifications and requirements. Web a process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. Access vital capability for reports and track cpk/ppk. The base of the calculation is a spreadsheet without macros. Web sample capability assessment worksheet. Web the steps for conducting a process capability study are: Just drop in your data. Web process capability analysis: Comparing the output to the spec. Web a good practice to capture the reliability of our pp estimate is to use minitab’s confidence intervals, available in stat>quality tools>capability analysis>options. Web a process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. It involves collecting data on. Qi macros can do it for you right in excel. To calculate adjusted values, you need the microsoft certified „sixsigmablackbelt analysis“ excel „add in“. You can make all adjustments like: On the contrary, the icc for the primary outcome was 0.033, while an icc of 0.050 was used in the sample size. Access vital capability for reports and track cpk/ppk. Calculates cp cpk and pp ppk in seconds. You can make all adjustments like: Web how to perform a process capability study. To calculate adjusted values, you need the microsoft certified „sixsigmablackbelt analysis“ excel „add in“. It involves collecting data on process characteristics and calculating. On the contrary, the icc for the primary outcome was 0.033, while an icc of 0.050 was used in the sample size. Calculates cp cpk and pp ppk in seconds. A few ways a process capability study. To calculate adjusted values, you need the microsoft certified „sixsigmablackbelt analysis“ excel „add in“. Web capability analysis is a critical tool for ensuring. On the contrary, the icc for the primary outcome was 0.033, while an icc of 0.050 was used in the sample size. Web need to calculate cp cpk for attribute data? Web a process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. Web struggling with. Web how to perform a process capability study. The base of the calculation is a spreadsheet without macros. Access vital capability for reports and track cpk/ppk. Web business capability analysis technique template. Web process capability analysis: Comparing the output to the spec. Web process capability study helps in product and process design, vendor sourcing, production planning, and manufacturing process control. Web capability analysis is a critical tool for ensuring process performance meets specifications and requirements. Calculates cp cpk and pp ppk in seconds. Qi macros can do it for you right in excel. A few ways a process capability study. On the contrary, the icc for the primary outcome was 0.033, while an icc of 0.050 was used in the sample size. Web need to calculate cp cpk for attribute data? Web a process capability study uses data from an initial run of parts to predict whether a manufacturing process can repeatably produce parts that meet specifications. The following is an excerpt from the quality engineering handbook by thomas pyzdek, © qa publishing, llc. Web struggling with process capability analysis?

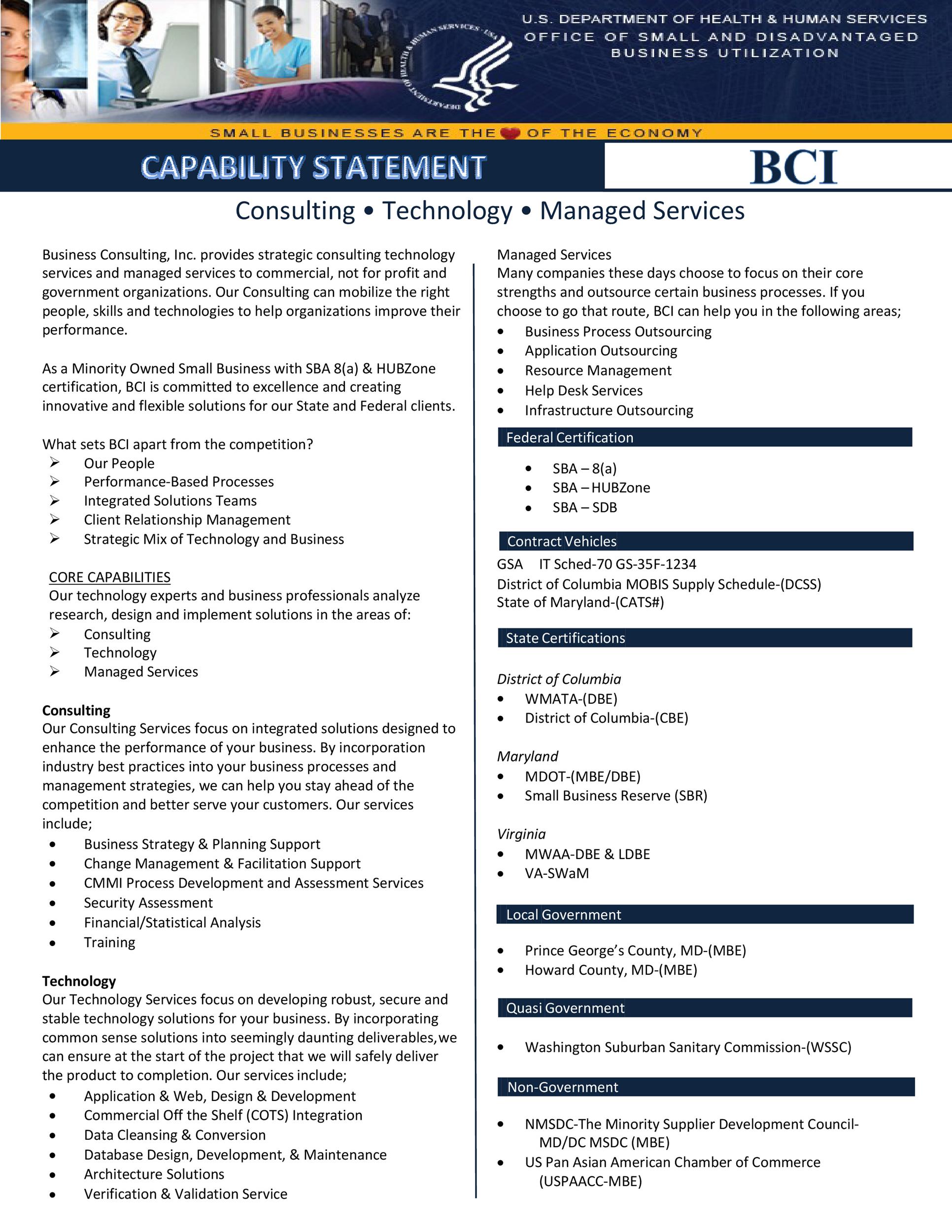

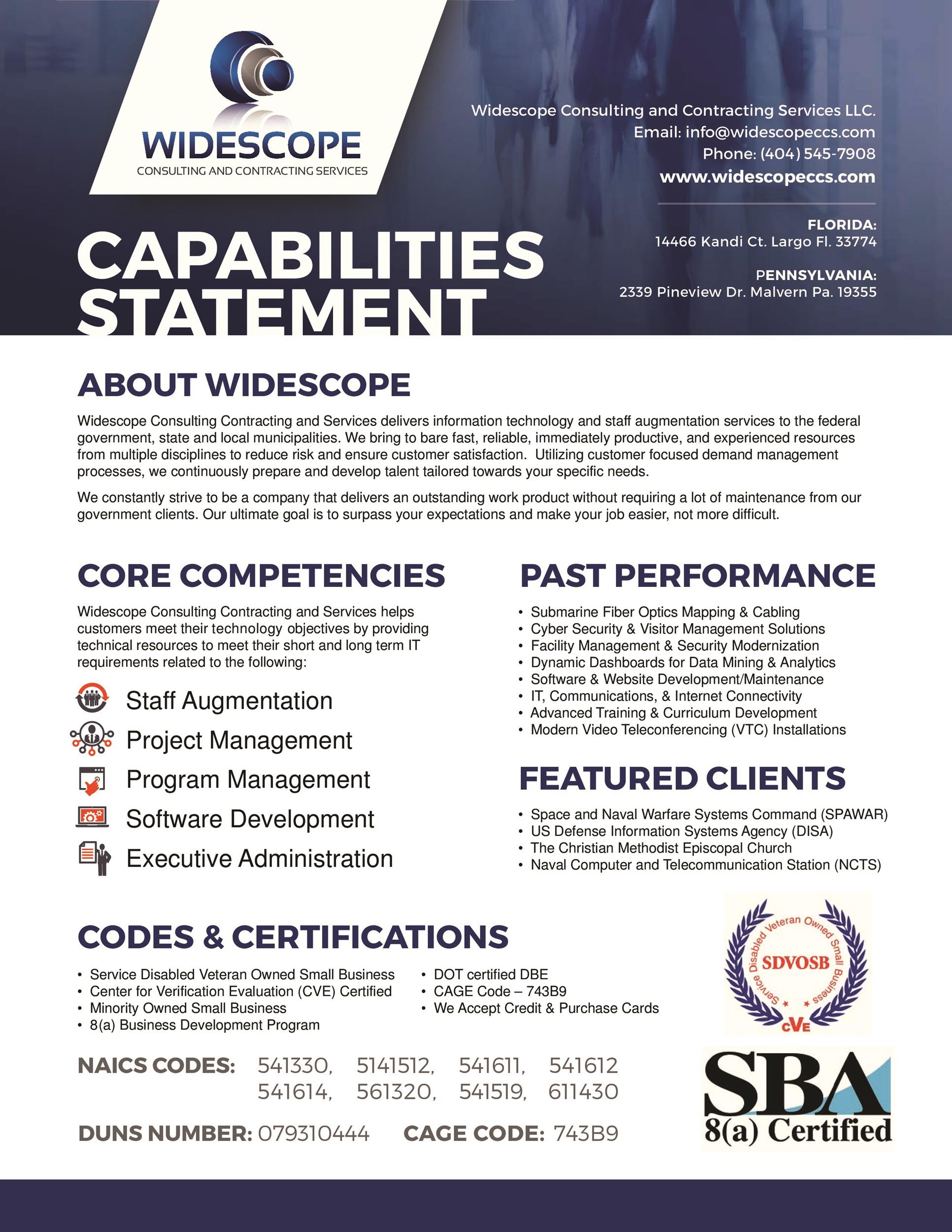

39 Effective Capability Statement Templates (+ Examples) ᐅ TemplateLab

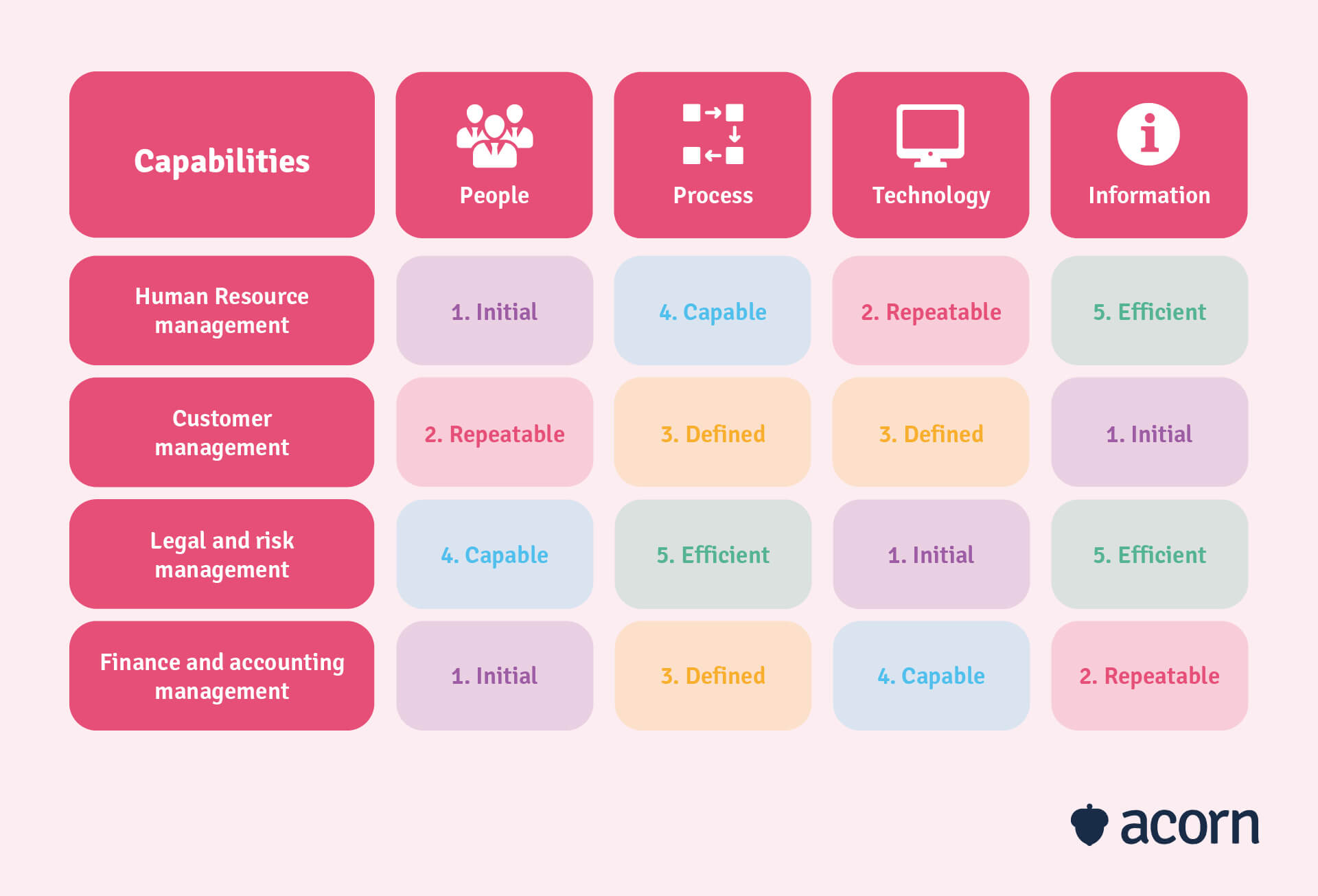

The Howto Guide to Effective Capability Assessment Acorn

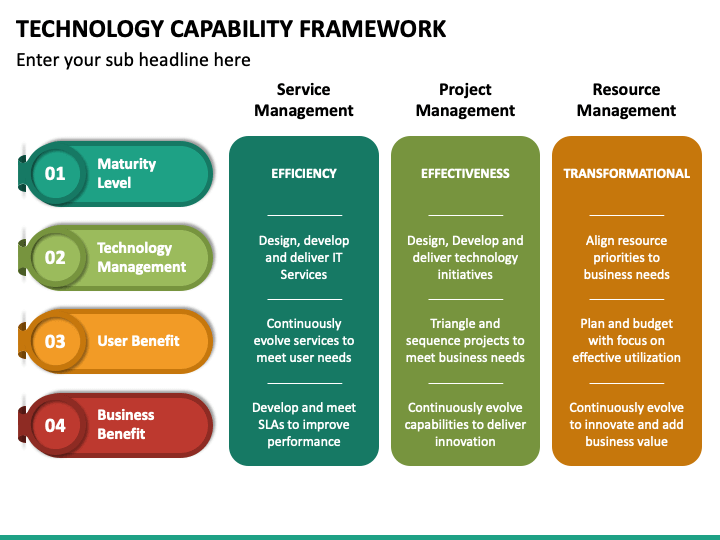

Capability Assessment 03 in 2021 Infographic powerpoint, Powerpoint

Business Capability Map Template

How To Do A Capability Study In Excel Study Poster

Capability Study Template

Capability Gap Analysis Template SampleTemplatess SampleTemplatess

39 Effective Capability Statement Templates (+ Examples) ᐅ TemplateLab

39 Effective Capability Statement Templates (+ Examples) ᐅ TemplateLab

Capability Study Excel Template SampleTemplatess SampleTemplatess

When To Use This Template:

Web The Steps For Conducting A Process Capability Study Are:

A Template Can Significantly Streamline The Process And Ensure Consistent Results When Conducting A.

It Involves Collecting Data On Process Characteristics And Calculating.

Related Post: