Lean Standard Work Template

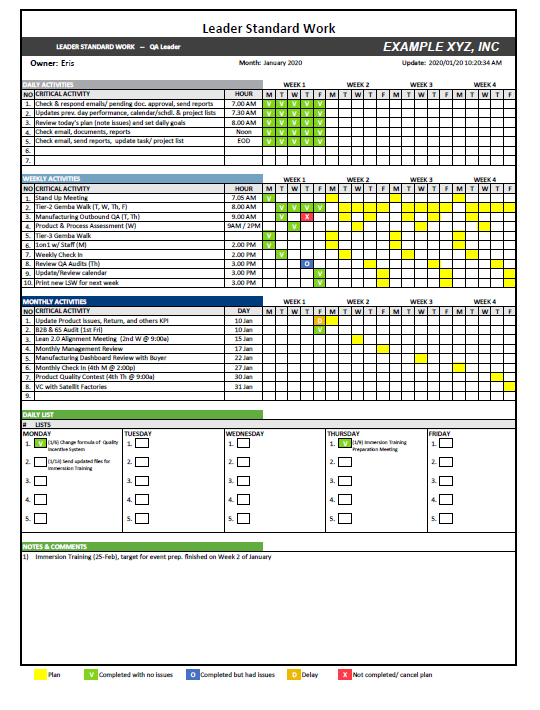

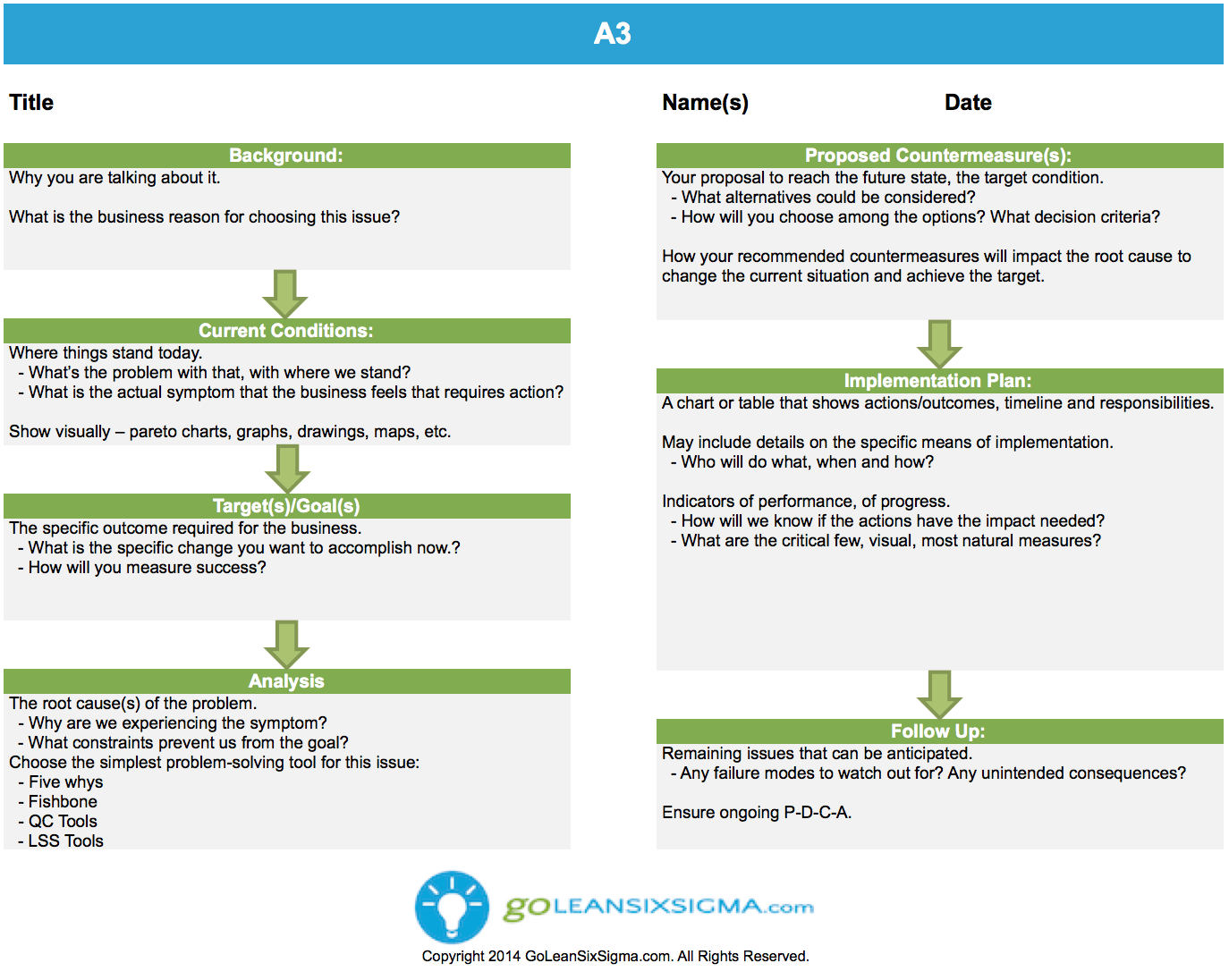

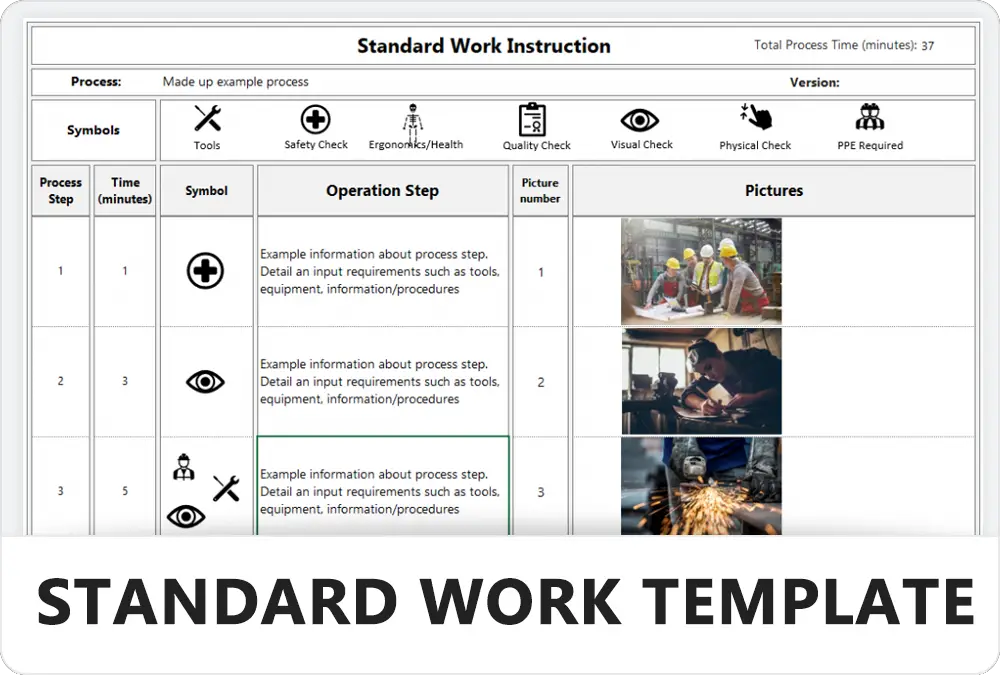

Lean Standard Work Template - This is your standard time. Web leader standard work is a systematic, structured approach that defines the key activities and behaviors to be performed by leaders at various levels within a manufacturing organization. It helps improve safety, increase efficiency, enhance quality, reduce waste,. Identify the process to be improved. The term “lean ergonomics data sample” became familiar, and its naming and use meant that the entire content of methods and kpis per work process. Web the standard work instructions (swi) excel template and google sheets a premade templates for streamlining and standardizing your business processes. Identify bottlenecks and areas for improvement. Assemble lean six sigma project team. Lsw provides consistency during leadership transitions. Whether you’re a green belt or black belt, these lean six sigma templates can support your dmaic process. It helps companies reach their improvement targets, but also provides a stable, reasonable working environment for frontline employees.learning how to standardize a process using this. Web leader standard work is a systematic, structured approach that defines the key activities and behaviors to be performed by leaders at various levels within a manufacturing organization. Map the existing process workflow. Lean principles. The title is the first thing anybody reading the template will see. Available production time per day ÷ customer demand per day = takt time. Tailored to suit various tasks, machines, or work environments, swis are particularly beneficial for processes demanding consistent and. This template is free to download and simple to use, making it an ideal solution for both. Web standardized work combination table. Lsw provides consistency during leadership transitions. Web the benefits of using a leader standard work template include: Leaders have a systematic and repeatable method to focus on both outcomes and processes. It can be very helpful to identify the waste of waiting and. This addresses the problem of process participants developing their own preferred ways of completing. Templates are free to download and customize. Web the standard deviation in minutes per work process and the percentage standard deviation from the specified time thus function as the necessary managerial variables in the method. Templates by dmaic phase by category all most popular […] Web. It is a key component of continuous improvement since it supports the reduction of variation in how a process or process is performed. Assemble lean six sigma project team. With the glss membership, get access to all of our courses and learn how to use all these tools! This addresses the problem of process participants developing their own preferred ways. This form is a more precise process design tool than the operator balance chart. Web the formula is as follows: Decide on key performance indicators. Standard work prevents the slide back to less efficient work practices. Standard operating procedures are used for production staff, to describe was needs to be done and how to do it. It locks in gains and provides a foundation for future advances. Map the existing process workflow. Identify the process to be improved. For supporting functions and managers, defining standard work can be more challenging, especially since their work cannot be planned 100%. Ensure that the title is clear and easy to understand. Leaders have a systematic and repeatable method to focus on both outcomes and processes. 0 580 7 min read. This addresses the problem of process participants developing their own preferred ways of completing. It involves documenting the best way to perform a task or process, creating standard procedures, and training employees to follow them. Lsw provides consistency during leadership transitions. It is a set of documented and standardized daily routines and behaviours that guide leaders in their roles, ensuring they consistently deliver value to their organizations. Tailored to suit various tasks, machines, or work environments, swis are particularly beneficial for processes demanding consistent and. Since the work instruction template shows your employees how to accomplish a task, one of the. Web standard work is a precise explanation of the current best practices for carrying out the steps of a process. Web leader standard work is a systematic, structured approach that defines the key activities and behaviors to be performed by leaders at various levels within a manufacturing organization. It is a key component of continuous improvement since it supports the. Practical lean standard work is a foundation element of lean manufacturing methodologies. Leaders have a systematic and repeatable method to focus on both outcomes and processes. Without it, the gains made from the other lean tools, such as visual management, 5s, work cells, flow production, and continuous improvement, will only be short lived. It helps companies reach their improvement targets, but also provides a stable, reasonable working environment for frontline employees.learning how to standardize a process using this. This form is a more precise process design tool than the operator balance chart. The term “lean ergonomics data sample” became familiar, and its naming and use meant that the entire content of methods and kpis per work process. Standard operating procedures are used for production staff, to describe was needs to be done and how to do it. One of the fundamental principles of lean manufacturing is standardized work, which involves establishing precise procedures to make products in the safest, easiest, and most effective way based on. Lsw drives continuous improvement and fosters a culture of team. This is your standard time. Try smartsheet for free, today. When to use this template: Web download the blank lean business model canvas template for google slides. Tailored to suit various tasks, machines, or work environments, swis are particularly beneficial for processes demanding consistent and. Also called standardized work, standard work is key to maintaining stability, solving problems effectively and scientifically, and kaizen (continuous improvement). Web the standard deviation in minutes per work process and the percentage standard deviation from the specified time thus function as the necessary managerial variables in the method.

Standard Of Work Template

10 Lean Standard Work Template Perfect Template Ideas

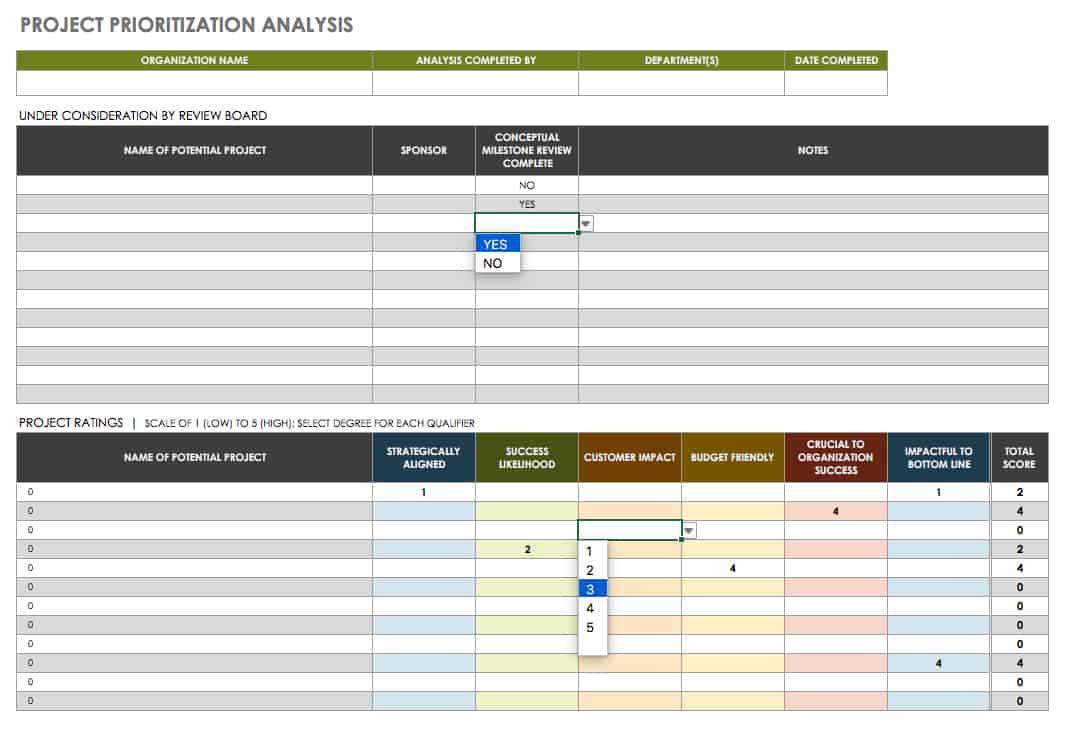

Free Lean Six Sigma Templates Smartsheet

How to Write a Standard Work Template for Your Team (+ Free Template

Standard Work The Foundation for Kaizen Lean Smarts

A Lean Journey Digital Leader Standard Work With HabitHub

How To Establish Consistent Production Though Lean Standard Work

30+ Free Lean Tools, Templates & Examples

Standard Work Instructions Template (Excel) Learn Lean Sigma

10 Lean Standard Work Template Perfect Template Ideas

Lsw Provides Consistency During Leadership Transitions.

It Is A Key Component Of Continuous Improvement Since It Supports The Reduction Of Variation In How A Process Or Process Is Performed.

Identify The Process To Be Improved.

Web Standard Work Is One Of The Fundamental Disciplines Of The Toyota Production System (Tps) And Lean Manufacturing.

Related Post: