Pfep Template

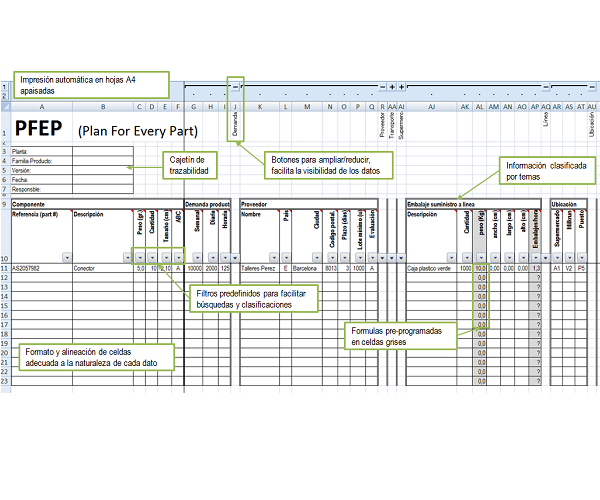

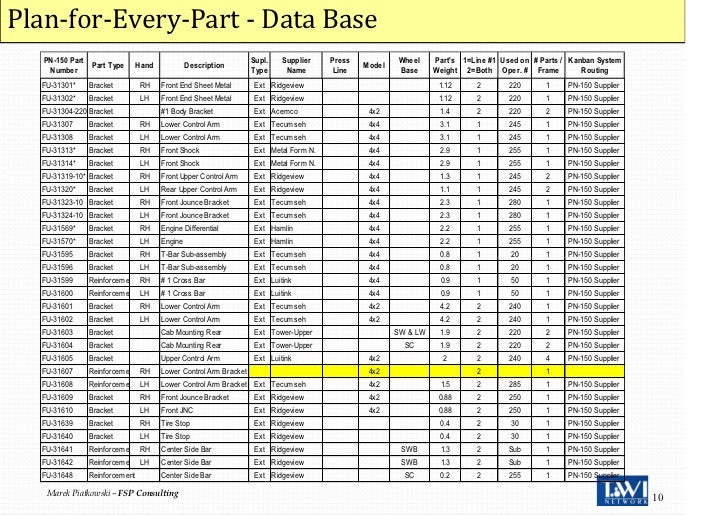

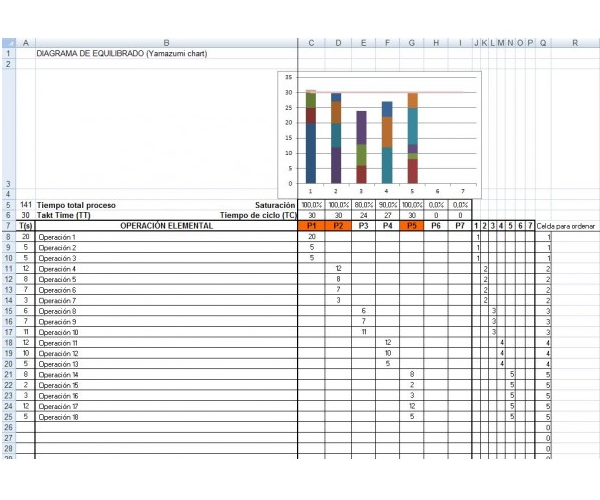

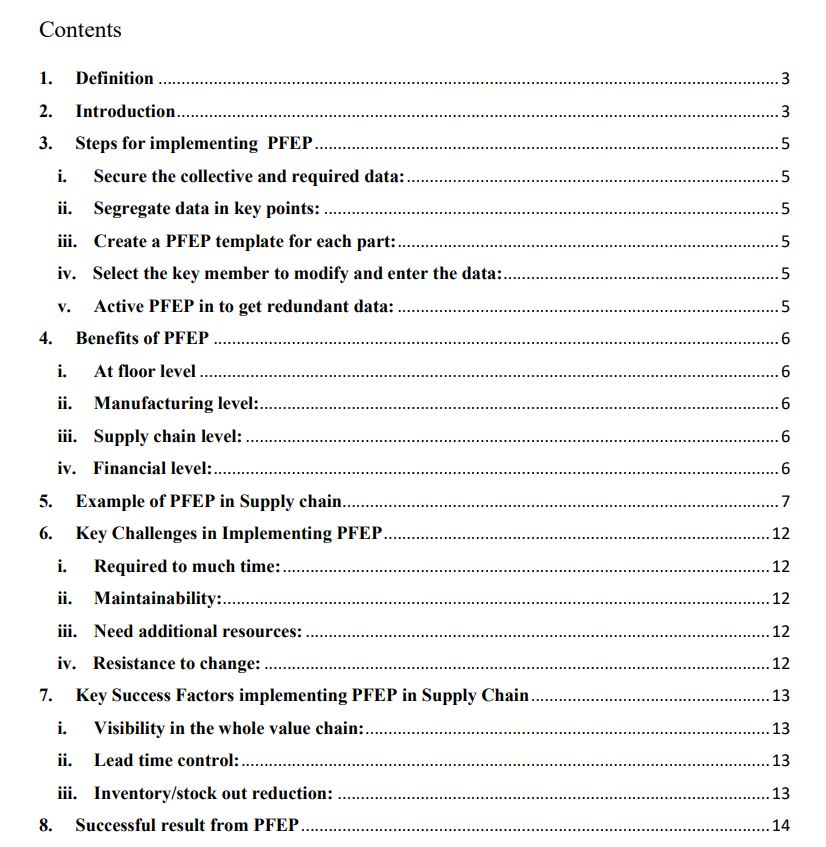

Pfep Template - What is a pfep, a plan for every part? Web plan for every part (pfep) enables companies to develop a detailed plan for every component or part required for manufacturing. It connects data points of the organization and makes a product, material, and. Web the “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. Web learn how to create a detailed plan for every part used in lean production from chris harris, a leading pfep theorist, in this free document. Web learn what is plan for every part (pfep), a blueprint for effectively managing logistics and manufacturing aspects of a part. Web learn the steps to create a spreadsheet pfep template and how to use it to plan every part in your supply chain. Web a detailed plan for each part used in a production process, showing everything relevant to managing the process with no errors or waste. A “plan for every part” or pfep in lean manufacturing is the ultimate goal of lean engineering. Web learn more about the advantages of leandna’s inventory optimization and daily automation. What is a pfep, a plan for every part? Web learn how to employ plan for every part (pfep) strategies to improve efficiency, standardization and quality in the ordering and delivery process. Each template can involve information only related to that product, and. Learn the plan for every part pfep meaning along with lean manufacturing. Under the a plan for. Learn the typical information included in a pfep, guidelines on the data to use,. Web learn how to employ plan for every part (pfep) strategies to improve efficiency, standardization and quality in the ordering and delivery process. A “plan for every part” or pfep in lean manufacturing is the ultimate goal of lean engineering. An acronym is originating from the. Web learn 10 actions to improve your pfep (plan for every part) process with automated pfep software, such as enriching data quality, standardizing templates, and using predictive. This includes identifying a specific part. In this article, we will examine. Web learn more about the advantages of leandna’s inventory optimization and daily automation. Web a key step is to create a. It connects data points of the organization and makes a product, material, and. Web standardizing your pfep template will improve your team’s productivity as teams will spend less time manipulating data. Web the “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. Web pfep is a material flow plan that. It helps managers to make. This is a critical tool in the toyota. An acronym is originating from the lean community. What is a pfep, a plan for every part? Learn the typical information included in a pfep, guidelines on the data to use,. Find out the common data elements, storage plan,. Web what is pfep, or plan for every part? Web a key step is to create a comprehensive parts database, called a plan for every part, or pfep. It connects data points of the organization and makes a product, material, and. Web learn how to employ plan for every part (pfep) strategies. It helps managers to make. Web standardizing your pfep template will improve your team’s productivity as teams will spend less time manipulating data. Web learn 10 actions to improve your pfep (plan for every part) process with automated pfep software, such as enriching data quality, standardizing templates, and using predictive. Web pfep is a systematic approach to managing the flow. Web a pfep is a spreadsheet or database that contains all the pertinent information about every part or raw material required for a producer’s end products. Web the “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. A “plan for every part” or pfep in lean manufacturing is the ultimate. In this article, we will examine. It connects data points of the organization and makes a product, material, and. Web pfep is a material flow plan that includes specific data on. The pfep is used to define a plan (at part level) for the most efficient. Web learn the steps to create a spreadsheet pfep template and how to use. It helps managers to make. Learn the plan for every part pfep meaning along with lean manufacturing. Find out the common data elements, storage plan,. Web why a plan for every part? Web plan for every part template. Web pfep is a systematic approach to managing the flow of materials, information, and resources throughout the production process. Under the a plan for every part. Learn the typical information included in a pfep, guidelines on the data to use,. In this article, we will examine. The pfep is used to define a plan (at part level) for the most efficient. Web a detailed plan for each part used in a production process, showing everything relevant to managing the process with no errors or waste. Web why a plan for every part? Web learn how to employ plan for every part (pfep) strategies to improve efficiency, standardization and quality in the ordering and delivery process. You can download the plan for every part template along with the guide. Traditionally derived from lean best practices, a pfep can. Web learn how to create a detailed plan for every part used in lean production from chris harris, a leading pfep theorist, in this free document. Web a pfep is a spreadsheet or database that contains all the pertinent information about every part or raw material required for a producer’s end products. Web learn more about the advantages of leandna’s inventory optimization and daily automation. Web learn the steps to create a spreadsheet pfep template and how to use it to plan every part in your supply chain. This is a critical tool in the toyota. This includes identifying a specific part.

PFEP (Plan for Every Part) Creative Safety Supply

PLANTILLA PFEP (PLAN FOR EVERY PART) LEANBOX

PPT PSLPI PFEP Plan for Every Part Presentation (33slide PPT

How to Leverage Plan For Every Part (PFEP) in Supply Chains GEP Blogs

What is Plan For Every Part (PFEP) 4 Main Benefits

PFEP (Plan For Every Part) Optimize Your Entire Supply Chain

Plan For Every Part Template & Guide

Plan For Every Part Template

PLANTILLA PFEP (PLAN FOR EVERY PART) LEANBOX

Plan For Every Part Template & Guide

Web Plan For Every Part (Pfep) Enables Companies To Develop A Detailed Plan For Every Component Or Part Required For Manufacturing.

It Helps Managers To Make.

Web A Key Step Is To Create A Comprehensive Parts Database, Called A Plan For Every Part, Or Pfep.

Web The “Plan For Every Part” (Pfep) Methodology Is A Powerful Tool That Streamlines Operations, Minimizes Waste, And Optimizes Inventory Management.

Related Post: